Add to Cart

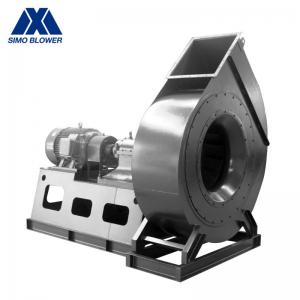

Coal Gas Boosting And Conveying Ventilation Stainless Steel Blower

Introduction

The Stainless Steel Blower can be used as the blast for various furnace forging furnaces.

Coal Gas Boosting And Conveying Ventilation Stainless Steel Blower is also suitable for conveying air and non-corrosive, non-self-igniting, non-viscous materials or light powder/debris/short fiber materials.

Coal Gas Boosting And Conveying Ventilation Stainless Steel Blower is suitable for forced ventilation, forced cooling, blasting of smelting furnaces and foundry furnaces, pressurization or decompression sealing of industrial equipment.

Technical data

| series | model | Stainless Steel Blower Rotation Speed | Stainless Steel Blower Total Pressure | Stainless Steel Blower Air Capacity | Power (kW) |

| 9-11 Stainless Steel Blower | 4D | 2900 | 2285~2452 | 3297~6594 | 5.5~7.5 |

| 4.5D | 2900 | 2893~3060 | 4695~9389 | 11~15 | |

| 5D | 2900 | 3570~3854 | 6440~12880 | 15~22 | |

| 5.6D | 2900 | 4482~4805 | 9048~18095 | 30~45 | |

| 6.3D | 1450 | 1422~1500 | 6441~12882 | 7.5~11 | |

| 7.1D | 1450 | 1804~1942 | 9220~18439 | 11~18.5 | |

| 8D | 1450 | 2285~2462 | 13189~26378 | 18.5~30 | |

| 9D | 1450 | 2893~3099 | 18779~37558 | 37~55 | |

| 10D | 1450 | 3570~3854 | 25760~42933 | 55~90 | |

| 11.2D | 960~1450 | 1961~4835 | 23961~72381 | 30~160 | |

| 12.5D | 730~960 | 1412~2638 | 25329~66620 | 22~90 | |

| 14D | 730~960 | 1775~3305 | 35586~93596 | 45~160 | |

| 16D | 730~960 | 2314~4295 | 53120~139712 | 75~280 | |

| 4D | 2900 | 2069~2187 | 3297~6594 | 5.5~7.5 | |

| 4.5D | 2900 | 2618~2766 | 4695~9389 | 11~15 | |

| 5D | 2900 | 3227~3413 | 6440~12880 | 15~22 | |

| 5.6D | 2900 | 4050~4286 | 9048~18095 | 30~37 | |

| 6.3D | 1450 | 1285~1383 | 6441~12882 | 5.5~7.5 | |

| 7.1D | 1450 | 1628~1746 | 9220~18439 | 11~15 | |

| 8D | 1450 | 2069~2226 | 13189~26378 | 18.5~30 | |

| 9D | 1450 | 2618~2824 | 18779~37558 | 30~55 | |

| 10D | 1450 | 3227~3481 | 25760~51519 | 55~90 |

Advantages and Features

1.The fan can output very high pressure, suitable for any need to transport high pressure & normal temperature gas industrial occasions.

2.Small size, compact shape, can be placed in a small space.

3.Simple installation, do not need the support of professional technician.

4. High energy transfer efficiency. All the energy of the motor ACTS directly on the impeller, and there is no energy consumption in the transmission process.

5.Made of high quality carbon steel, Stainless steel or other metal materials can also be used according to user requirements.

6. Running test and vibration value test after the production is completed, the operation is reliable.

FAQ

1. What parameters need to be provided when you design the industrial centrifugal fans?

Answers: Air flow, total pressure or static pressure, inlet temperature, local voltage and frequency, Altitude etc.

If there is flammable and explosive gas, or big dust loading in the medium, please also inform the designer.

2. How about your company’s pre-sales service and after-sales service?

Answers: Before our cooperation, we have the professional technical team to help you make the technical solution according to your working condition, to make sure the centrifugal fan efficiency operation.

After sales service, we will offer 12 months’ repairing service, and provide lifelong follow-up services. Besides, our engineers are available for going abroad to offer the repairing service.

3. Does your company have qualifications?

Answers: SIMO Blower has obtained ISO 9001-2008, CE, BV certifications and so on.